Brewery – The multiplier protein factory

This case is part of a case series written by Alexander Prinsen. It is the outcome of a research project where dozens of cases where analysed for their potential to merge (eco)Logical Thinking with (eco)Nomic Doing. The cases series are a first summery of main examples which are transformative for their industry. Each of these cases provide breakthrough thinking and scientific evidence how Physics, Biology and Green Chemistry can solve environmental degradation, provide better products, generate profitable business cases and contribute to the whole system we call home, Spaceship Earth.

Author: Alexander Prinsen, Rotterdam, The Netherlands

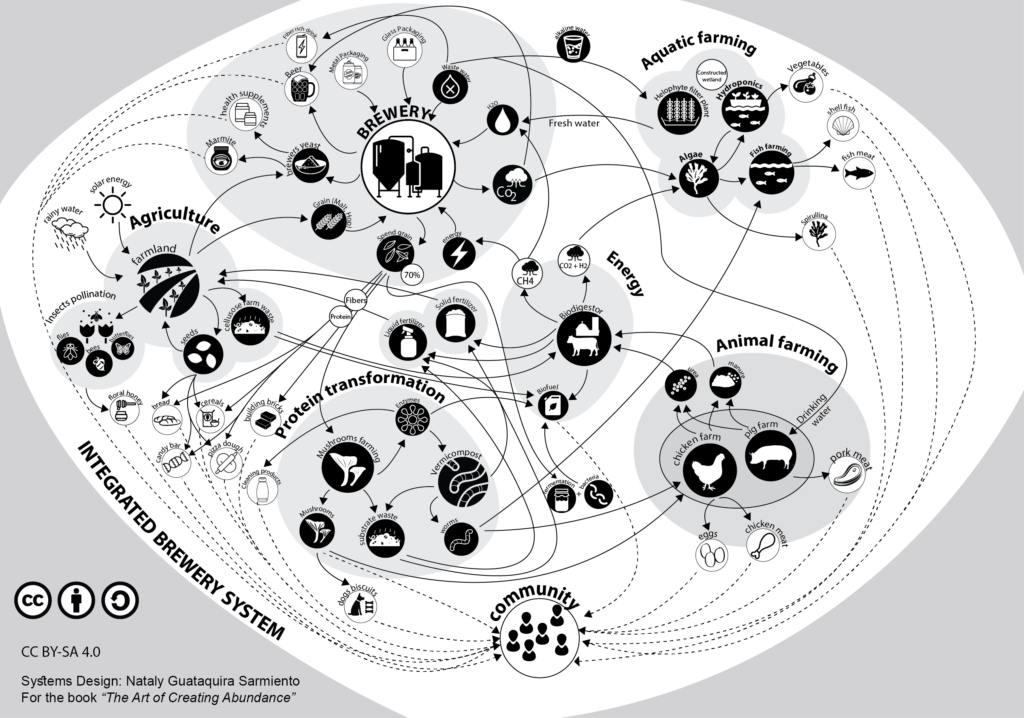

Systemic Design Image: Nataly Guataquira Sarmiento, Turin, Italy

Version: 05 November 2019

Review status: Permanent Beta Version

Tags:

Soil restoration; Fertilizer; Farming (Barly); water cleaning; yeast; Energy; Water Aquifer; 5 kingdoms of Nature; plant filtering, Digester, biogas; Micro brewery; fermentation; integrated systems;

The relevance of this case

Our large food supply chain wastes over 70% of the crop, wastes over 30% during transport, food processing industry wastes water and leftovers and the remainder used by consumers is wasted as leftovers. In a world where there is still hunger and our food distribution is unequally distributed, there is doubt whether we can feed 10 billion people in 2050 and feed our livestock with what the land produces. To answer this question it requires a redefinition of what food actually is for whom.

To redefine the human concept of food, the answer comes from looking at how the five kingdoms of nature transform and cascade the available nutrients. In their nutrient system there is no waste and every molecule is constantly transformed into new applications. So if we want to feed and provide fresh water to 10 billion people and our livestock we need to include also the whole value chain as potential food production system. It is when the systemic connections between agriculture and food processing are made; it becomes transparent and evident how the food processing industry is actually a system of small bio-refineries. Each bio-refinery unit is central in the value chain where they operate in and are key in transforming and redistributing the nutrients they use.

This is also the case for breweries which are central in this case. We will investigate how much more value their nutrients have when they are cascaded through a much larger transformation system than the current practise. In fact a brewery is part of a much larger system. Therefore understanding how the individual subsystems can be connected and how this reconnecting will impact the quality of the beer itself.

In general breweries business models are focused on 30% of their output which is the actual beer and the other 70% is seen as waste (70% of the spent grain and 70% of the water). The spent grain is mostly used to feed animals (cows and pigs), although this is a suboptimal feedstock. The wastewater is treated before being disposed. This shows brewing beer has direct links with:

1) Regenerative Agriculture (is the system able to stimulate organic farming)

2) Regenerative Water Management (is the system able to use water effectively to fill aquifers and provide fresh drinking water)

3) Protein production (is the system able to produces more protein as a whole)

4) Bio Energy production (is the system able to provide the energy needed)

5) Packaging (is the system able to eliminate micro plastics)

6) Climate change (is the system able to impact Land use and climate emissions)

The importance of clean non toxins value chains, it is becoming evident as even beer does not escape the contamination thanks of human doing. It is scientific proven Glyphosate can be found in beer, which have accumulated in the plants seeds of the barley and malt crops.. And also micro plastics have found their way into beer through the water sources breweries use. Despite the German Purity Law (Reinheitsgebot this has not prevented beer to become polluted with toxic particles which are now cascading through our natural system.

Systemic Value Chain

The above points are all systematically connected. This implies each brewery must be seen as a part of a larger value chain in which all nutrients are cascaded. It is only then when it becomes evident the brewery has a much larger responsibility in how it produces and transforms its nutrients. The brewery shares its responsibilities with its farmers in how they produce the barley and hop. The brewery has responsibility how it extracts, uses and restores fresh water supplies. And finally the brewery is responsible in how it takes care of the precious content of the leftover seeds (spent grains). Only through a systemic approach it is possible to cascade and valorise all remaining 70% secondary product flow (water and spent grains) into high value added products. On average it is estimated these types of breweries can produce seven times more food, fuel, and fertilizer than a conventional operation and four times as many jobs. (*Mshigeni, 2001; Saunders, 2000)” (Towards a Deeper Philosophy of Biomimicry Article in Organization & Environment · February 2011 Impact Factor: 1.39 · DOI: 10.1177/1086026611425689).

The whiskey breweries apply similar process steps for their waste streams(Wastewater, spent lees and pot ale). The Pot Ale is found to be useful as protein source for the salmon industry in Scotland. The Pot Ale can also be fermented into biofuel and other derivatives like Acetone. The Spent Lees can be fermented into biogas as power generator. So the brewery and distillery industry are starting to catch up and who knows soon your brewery will follow suit!

Introduction to fermentation

However before we can move towards the systemic design, some basic understanding of the fermentation process of beer is required. Firstly humans did not invent alcoholic drinks. It is a process which occurs spontaneously in nature. Because Fruits and seeds are high in sugar content, they will start to spontaneous ferment (we call rotting) when they are ripe (eg contain the highest sugar concentration) thanks to microbes living around the plant. The air, soil and plant contain a natural occurring microbiome of bacteria, yeast and fungi. And when sugar suddenly becomes available they can start to feast.

Especially yeasts are responsible for the alcohol production. Yeasts are micro-organisms part of the Fungi Kingdom and the specialists when it comes to turning available sugars into alcohol. A fun fact is that even Animals know when it is time feast on the ripe fruits and like humans also get drunk as a result. You can find various online videos about this phenomenon. Their by-product CO2 (or to use a human analogy they exhale CO2) during their consumption of sugar. The yeasts are naturally present all around us, in the soil, on the skin of Animals (including Humans), on the flowers and fruits of the plants, in oceans and also in the air.

Interesting enough Humans have learned to cultivate and use the tricks of the microbes for more than 10.000 years. Humans learned they are very beneficial and even probiotic for their food production. The ancient tradition of wild/spontaneous fermentation (natures composting technique) is seen as a way to conserve food and it originates from Asia. They are used for making bread, making Cheese, Salami, Mozzarella, Kombucha and so many other delicious food sources. If you want to read more about fermentation, I recommend you to read “The Art of Fermentation” by Sandor Katz, which gives an excellent introduction to Fermentation and its’ influence on the human way of living.

The substrate consists of grain/ cereals (malted barley and other grains), Hobs where water, yeast and sugar is added to produce an alcoholic outcome. It is not very strange beer is referred as “liquid bread”, as it contains significant amounts of nutrients derived the cereals, like magnesium, selenium, potassium, phosphorus, biotin, chromium and B vitamins. Even Brewer’s yeast (single cell fungi) is known to be a rich source of nutrients. Interesting enough the taste of beer is also influenced by the water. The different mineral components in the used water supply are responsible for the different types of beer we know today, making beer brewing more local than we would image today.

In the old days brewmasters, farmers and the water source had a very close relationship, as the cereals come from local farmers, the left over spent grain was fed to pigs and partly also used to fertilize the land on which the cereals grow. Nothing was wasted as everything could be reused for a new process.

The early pioneer case and legacy of Tunweni Brewery

It was the Tunweni brewery owned by Namibian Breweries in Tsumeb Namibia which has become the global example of a zero emissions brewery. It was the first of its kind in which nutrients continuously generate new values streams using nature’s principles. It has developed an integrated farming system philosophy for its development of this zero emissions brewery system. Creating these systems requires a in depth understanding of the biological and chemistry of nature’s patterns to value the unique aspects it provides. This brewery has been the inspiration for other breweries on how to create an integrated system.

So how did this story begin? It all started in 1997 when the Namibian Breweries owner Werner List wanted to lower the cost structure of his new Tunweni brewery in Tsumeb. Tsumeb had a long mining history and is the gateway towards various natural parks. The brewery would serve the local and international market. The brewery was to be located in an agricultural area where sorghum, maize and sunflowers were farmed. Freshwater and energy (re)sources were scarce and the challenge was to create a renewable process. In addition Namibia imports all its chicken feed and 80 percent of its chickens so creating an additional local feedstock would eliminate the import costs.

It was due to the curiosity of the Werner List which lead him to learn about the work of prof. George Lai Chan and his collaboration with the ZERI foundation. In addition professor S.T. Chang from Hong Kong was invited to solve the nutrient flow of the spent grains. Thanks to the work of Chan solutions were found to use the alkaline wastewater and spent grain to create a connected value chain which was able to produce fertilizer, fresh water and feed by cascading the nutrients. This brewery system is able to sustain a local community in food, freshwater and be regenerative for the local agriculture system. With the help of this team the brewery would implement a world’s first zero waste integrated agriculture system with the brewery at its centre. It is one of the blueprints on how to design a regenerative and circular economic system.

The brewery systemic design

Over the last decades the Tunweni brewery design expanded as more innovative solutions arrived to the market. Let us take a close look at why breweries are relevant cash flow multipliers to the local community and its ecology.

Now let us start putting the system together so it wastes nothing. It is here where the visionary work of Professor Chan comes into play. Professor Chan showed during the Tunweni brewery project how such integrated systems could be created using only local resources. Interestingly Professor Chan was educated as a civil engineer for a large part of his life when he wanted to retire; however fate had other plans. During his travels in China he learned from the farmers that it was possible to integrate nature’s wisdom into a working (integrated farming) system. The Chinese farmers taught him how to design integrated farming systems which waste nothing and create multiple benefits out of the system. The trick is understanding the connects between existing living systems, using the output of one system as the input for another system. The game was not waste any valuable resources and as such nutrients, water and energy must keep flowing inside the system. Realising the huge impact this knowledge would have, he decided to extend his career sharing his new insights with the world. Over time he has been implementing dozens of systems across the globe could.

This Integrated farming system approach has now many names: China (ecological farming), Columbia (integrated food & waste management systems) & Fiji (integrated farming systems), India (integrated biogas farming) and South Africa (BEAT Coop & African Agroecological Biotechnology Initiative.

For starter traditional breweries uses the input resources consisting of water, cereals (hops, barley), yeast and energy to control a fermentation process where the seeds are being converted to the beer as we know. Its output streams are in general the primary product, the beer (only 20% of total output), and secondary products; firstly the used/spend cereals (mash/grain) (generally 80% is left of original seeds); secondly the alkaline wastewater (the remaining 80% of the input); and thirdly carbon dioxide generated by the fermenting yeast.

First: Upgrading spent mash/grain

In general most traditional breweries sent the spent grain (residue of malt and grain) to landfills. Others sent it to farmers to be used as low grade feedstock for cattle. It is a low grade feedstock because of the long chains of carbohydrates, the cellulose, and animals gut microbes find it hard to digest these fibres. Because of this less favourable digestion process the animals produce generally as result more methane as their digestive by-product. EcoBreweries have different options to turn this low-grade output into a high-value stream.

Option 1a: This conversion can be achieved using fungi as the natural transformation converter. They apply their enzymes (small organisms specialised in cutting hydrocarbons/fibres) in breaking down the strong hydrocarbons bonds, like cellulose and lignin, (which are nothing else than long sugars chains) as their primary nutrient food source. The output is a substrate containing much shorter sugar hydrocarbon chains including the mycelium of the fungi. This substrate is now a much higher-graded feedstock to digest as feedstock for animals, especially pigs and even worms as it now includes more amino acids than before. The beneficial outcome is the cultivation of mushrooms for feedstock and human consumption. In addition it is even possible to extract the enzymes from the substrate for other applications.

One of the challenges Chan faced was to find valuable solutions on how to deal with the spent cereals (grain). Convinced of the fact there must be a way to break down cereal celluloses into useful products, Professor Chan invited professor S.T. Chang, an expert on fungi, from Hong Kong to join the challenge. Thanks to Chang an appropriate fungi species was discovered which could consume the spent grain and produce edible mushrooms. His breakthrough made it possible to create a much higher nutrient value stream path for the spent grain. The fungi breakdown of the cellulose meant more amino acids could be produced making it a much better animal feedstock than feeding the original spent grains directly to the livestock. In addition the animals will produce much less methane because of this. In addition the fungi produced mushrooms creating an additional food source for the local community and its animals.

Option 1b: Alternatively part of the used fungi substrate can be used as an input for vermicomposting (using earthworms to do the transformation). The shorter carbohydrates chains are easy for the earthworms to consume making the substrate a very good breeding ground for them. In addition during their consumption the worms enrich the substrate by mixing more oxygen into the substrate. And in addition they as such further shorten the carbohydrate chains. The outcome is high quality compost (the solid part) and a fertiliser (the liquid part). The earthworms multiply themselves due to the high nutrient value of the substrate and the population excess is can be fed to fish and cattle. It is even possible to extract also the earthworm enzymes like those of the fungi to use them for detergents and other fermentation processes. Tunweni brewery implemented this option as part of their integrated system.

Option 2: The spent grain could also be used to produce dough for Bread, Candy bars, Pizza. To my surprise I tasted a spent grain bread when I visited the bakery of Taiwan beer in Taiwan. Unless the dough is used for low carbon hydrate diets (it’s is low in minerals and protein content because the beer and water washed out all the nutrients) the dough needs to be supplemented with additional seeds to compensate for the lower nutrient value.

Alternatively the spent grain can also be used as breakfast cereal when dried.

So suddenly the 80% wasted spent grains generate over 9 new cash flows in the whole system. The transformation of the spent grain makes it possible to create an additional protein source, Mushrooms, for human and animal consumption or when adding another step using worms, through Vermicomposting it will also produce fertilizer for crops and Worms as protein source for Fish and Chickens. In addition Enzyme can be extracted from the mushrooms substrate and worm’s substrate to be used for detergent applications. Once fully processed by the fungi and worms finally the left over spent grain is a high nutritional for feeding pigs and other livestock. The nutrient value of the spent grains are now fully utilised to benefit the local agricultural community where the grains originate. Alternatively the spent grain can be turned into dough (preferably adding local seeds to increase the nutrient value) for local bread like products.

Additionally new research found spent grains can also be applied to improve the porosity and thermal conductivity of red bricks.

Second: Upgrading and Rebirthing water for more protein

The production of beer requires large volumes of water acting as an solvent for the fermentation process. During the fermentation the cereals (Grains) and yeast interact with each other to produce the alcohol while at the same time extracting the nutrients from the cereals. Interesting enough breweries only sell the 20% of water used as bottled beers. The remaining 80% of used water becomes high alkaline (pH>7) solvent containing the remaining nutrient. Conventional breweries normally treated the water chemically to lower its PH level creating various environmental issues in the process. Or the brewery wastewater is put into a biogas production to extract the remaining energy value.

Option 1: It is in this part of the cascading where Professor Chan created an alternative loop. He knew the Spirulina Algae prefers alkaline water as growth medium [see also the Algae cases for more information] and with the nutrients it would have a natural feedstock. The Spirulina became an additional fast growing protein source to be integrated into the local economic system. Suddenly the brewery could valorise not only the spent grain also the wastewater making it possible to cultivate a biodiversity of aquatic life because the micro algae’s would also be able to sustain fish farming. And also it can feed livestock thanks to its probiotic properties. Together with the outputs from the spent grain system the fish could also be fed with the Worm.

The biodiverse aquatic system has become a symbiotic system mimicking a living ecosystem. It is able to further purify the water and produce fresh drinking water. The brewery can reuse again the 80% wastewater and would only need to replenish the remaining 20% from the local aquifer.

It is even possible to add a wetland system, if the location is suited, for more food production like vegetables, grains and other plants. Since then innovative minds have found alternative solutions applying bioreactors consisting of a large diversity of organisms, plants and microbes, to purify the water. The outputs are multiple depending on the plants used, for instance herbs and fruits. The company Bioplus is currently one of the innovation leaders in these systems. Or to quote the first Trappist brewery applying this system “it is rebirthing water again”.

Option 2: Alternatively farming communities who understood the nutrient value of the alkaline water used it as drinking water for their pigs.

Option 3: Recently breweries discovered the high nutrient value of the alkaline wastewater and the benefits of the fibres. These breweries have combined these two products creating a high fibre energy drinks. Like for instance the new product of Inbev.

So the water from the beer making process can be naturally purified by a natural system around the brewery. The life the water sustains is able to generate new value streams from the system. The cleaned water can be reused again for the next brewing batch, closing the cycle of the water flow. Or alternatively becomes drinking water for the feedstock, like chickens and pigs. As such it is providing new valorisation opportunities and raw materials for infusion into the beer.

Third: Produce Energy

To power an integrated brewery system one needs to harness the generated energy coming from the various transformation processes related to its output streams of spent grain and wastewater. Firstly the spent grain eventually becomes feedstock for livestock. The output of livestock (chickens, pigs, cows, goats), the manure, can be used as the input for a (bio)digester. It becomes more interesting when the pee and poo can be separated. For instance pics poo and pee in different places, so it is easy to collect the both flows separately. The digester produces methane (bio)gas which the brewery can burn to generate it’s energy or when there is an access of biogas it can be shared with the community.

The mentioned bioreactor system for the water cleaning, the biomass of the plants growing in the system can also be used as biodigester feedstock to produce more biological gas. Off course one can also choose to use the manure from the local community toilets to produce more biogas. The digester outputs are liquid and solid fertilizer use to regenerate the soil of the hops and barley. In addition one can also choose to use the mirco algae’s to produce biofuels as energy source.

Or when other sources of potential energy are available they can be harvested. Swinkels brewery is planning to use iron powder as an alternative energy source. Solar Cells are always a good solution to implement. And when rivers are nearby even gravitation vortex water turbines can be applied for electron harvest.

So by connecting livestock as part of the brewery system it can produce energy for the brewery using a (bio)digester for the energy production. This is increasing the output with many more options. And with new innovations coming to the market even more energy solutions can be added to the system.

Forth: Let the fermentation work for you

It is even possible for the brewery to create more outputs directly as a result of the brewery process. As we know at the core of the brewery is the fermentation process which requires Yeast to do the transformation. In the process the yeast will multiply itself thanks to the availability of sugar and minerals of the cereals. This natural process produces interesting enough two additional output streams for free. Firstly the excess yeast is harvested after the brewery process to produce Marmite and other Health supplements products. And secondly Breweries CO2 output emissions from the fermentation process and plant based burning (fossil and biogas) become new inputs. What most breweries have done is to capture and (re)use the CO2 emissions from the fermentation process (and sometimes also the CO2 emissions from the energy generation) to provide the sparkles to the beer. Thanks to the Reinheitsgebot those who followed it philosophy implemented this system with the help of companies like Pentair. Others start to use the CO2 emissions as growth medium for micro Algae’s and Bacteria boosting the biodiversity of the integrated system even further.

In addition with the increase consumption of alcohol free beer, this alcohol is becoming a waste product. Inbev Belgium teamed up with Ecover Belgium production site in Melle to provide alcohol for Ecover’s Detergents.

So by connecting the excess yeasts and their natural output emission (CO2) created by their transformation (fermentation) process suddenly the brewery produces besides beer also very healthy supplements, its beer bubbles and addition more nutrients to algae’s and bacteria. And also the alcohol produced for the free alcohol products found its use as detergents.

Fifth: Restore the Agricultural system

In the end the brewery system will only function and be sustainable when the soil where the seeds grow can be regenerative. This implies breweries are directly responsible for the soil they exploit for growing their seeds. Thankfully an integrated brewery system is able to sustain the agriculture system the brewery so depends upon. The breweries are therefore able to integrate the value added stream from the other subsystems with the agriculture. This effort will help accelerate the restoration of the hydrogen, carbon and nitrate cycle (and others), while also having direct influence on reducing the impact climate change will have on future harvests.

Interesting enough cereals crops rely to a lesser degree on pollination of insects as cereals are very similar to grass species. And grass is one of the few species who have figured out how to pollinate themselves using only the wind. This is called Anemophily. This is also the reason why grass is dense so it has the maximum opportunity of seed production with the help of pollination. Increasing it is also found insects do play a role in grass pollination, to what degree still needs to be answered. This implies beer might become more important as food source when other food crops start to fail to pollinate due to a lack of insects.

And as such they are able to close the local and global nutrient cycles to ensure the future supply of seeds are secured.

We learned the system produces fertilizer using fungi, worms, livestock and a biodigester (solid and liquid). When like the pigs the pee (containing high concentrations of nitrate) and poo is collected separately the pee can also directly be used as fertilizer for the grain and barley fields.

For example the Heineken Zoeterwoude brewery in the Netherlands is figuring out how to create a local regenerative system. One of their achievements is to increase the pollinator population again for their surrounding farmers, in this case the bees after decades of reduction. This proves how closely linked the brewery actually is in its surroundings.

So in the integrated system agriculture is the real pillar for a sustainable beer production. Without connecting the outputs from the larger system to agriculture the future of beer is put at risk. When done correctly the agriculture system is able to generate more revenue streams for the farmers and the connected entrepreneurs increasing the diversity of products which can be generated.

Sixth: Reducing Packing Material input

To package the output beer product breweries have a great impact towards their consumer’s and environment. For instance the famous plastic 6pack rings are strangling turtles and seagulls and therefore are being substituted with alternatives. Carlsberg solved this by using a biodegradable glue adhesive to connect the six pack. The Millercoors brewery has invented a biodegradable six pack ring which can be composted after use. And more innovations can be expected to emerge from other breweries too.

A Dutch innovation created a lightweight recyclable beer container from HDPE which can be endless reused as beer container. The biggest challenge for breweries is to solve the future shortage and environmental impact of packaging material like Glass, Cardboard and Aluminium cans.

So from a resource scarcity point of few, we can expect more bio-inspired packaging innovation coming to the market in the near future.

Realism

This case started with the Tunweni brewery as an example of what happens when a visionary business owner goes the long way. Thanks to his willing to take responsibility and raise the ecological bar of a brewery he found a team of scientific experts willing to make his vision happen. It is therefore even more unfortunate that after 7 years of operations the Tunweni brewery has to shut down due to changing geopolitical market situations. Since then Namibia or elsewhere the system has not been fully recreated to continue the experience and research evidence built up. The business economics shows integrated breweries are responsible for multiple new value streams in addition to beer.

Like in the old days breweries are starting to become part of the local ecology and they are taking their environmental responsibility. Not strange as Breweries use one of the most precious resources produced by nature namely Seeds and Yeast and Fresh Water which should not be wasted.

They need to show real stewardship for their local ecosystem as a total chain for upsizing their out streams for suppliers who support each other by passing the nutrients through the supply chain to the next in line. This implies breweries are more “social” enterprises which produce next to beer bread, mushrooms, biogas and as such jobs. It is the circular economy to its fullest potential.

Just image your local breweries start to leverage their outputs for urban farming ecosystems creating cascading effects within the community. With breweries it is possible to sustain a much larger food production system that generates abundance of local use of products and nutrients flow.

It requires little imagination to see a future where the consumption of beer becomes a service. We have seen how the value creation from an integrated brewery stream can produce so much more than just a glass of beer. The real value lies actually in the spent grain and alkaline water and much less in the production of the beer itself.

Other examples

The system is now being copied by local breweries all over the world. Those who succeed to integrate the system are able to compete on the local and global market due to the various cash flows.

In Montana (USA) the Wildwood Brewery from Jim Leuders is implementing the same system as a Tunweni Brewery. Leuders was actively involved with the implementation of the Tunweni Brewery and is now translating his knowledge to his own brewery. Leuders value chain is featured in the Biomimicry Database AskNature.org

In Ireland the N17 brewery, from Sarah Roarty, has moved a step further and added new product to the cascading system. Her brewery is using the leftover yeast as ingredients for marmite and health supplements. And in addition decided to use their mushrooms as feedstock for Dog Biscuits. She is transforming her wastewater through an aquaponics system.

Taiwan beer added a bakery to their brewery to use their spent grain to make bread. Actually it was here I had my first experience eating the bread from the brewery during lunch with the CEO of Taiwan Lung Meng Advanced Composite Materials (TLM) .

In Ohio (USA) the Great Lakes Brewing has integrated various aspects of the system into their brewery. They have a bakery, sell mushrooms and produce biofuels from their restaurant cooking oil.

And in The Netherlands the largest Brewery of Heineken is also investigating how they can become sustainable. They have been experimenting with filtering their wastewater using Algae’s and plants. Even the vortex is tested for cleaning the water. And Gulpener a local artisan brewery is implementing ways to upsizing their nutrients streams in their region including supplying a local bakery with spent grains!

Some other breweries worth looking into are Montfort Boys Town / Asahi Ibaraki Brewery / Shinano Brewery / Kirin Brewery / New Belgium brewery / Storm brewery / Erzquell Brauerei beistein / Mad river brewing / Neumarkter lammsbrau (*From Evelyn Echeverria (Author), 2009, Verwertung von Reststoffen der Meierhof-Privatbrauerei zum Aufbau eines integrierten Biosystems, Hamburg, Bedey Media GmbH)

Sources for further reading

Tunweni Brewery

Blue Economy – Gunter Pauli Case 109

asknature.org – http://vimeo.com/65674283

http://www.yesmagazine.org/issues/money-print-your-own/brewing-a-future-zero-emissions-in-namibia

http://www.travelnewsnamibia.com/news/zero-emissions-2005/

Professor George Chan

http://www.i-sis.org.uk/DreamFarm.php

http://www.i-sis.org.uk/HowtoBeatClimateChange.php

https://en.wikipedia.org/wiki/Zero_waste_agriculture

http://www.scizerinm.org/chanarticle.html

Irno Pretto Farm in Brazil : https://www.youtube.com/watch?v=0fFIg5WLnm0

http://www.appropedia.org/Integrated_Farming

www.scj.go.jp/ja/int/kaisai/ess2003/pdf_pre/s16_yasui.pdf

https://www.youtube.com/watch?v=Qt8qKbv9bP4 ; Integrated Farming System – English Version

http://www.agrifarming.in/rice-fish-farming/Livestock Feed Resources within Integrated Farming Systems, Professor Chan explanation on the system

Brewery innovations

http://www.heinekennederland.nl/duurzaamheid/2013/water/acties-en-resultaten/hergebruik-afvalwater

http://www.wageningenur.nl/nl/project/Algen-zuiveren-afvalwater-van-bierbrouwerij-1.htm

https://www.fastcompany.com/40536868/this-brewery-is-designed-as-a-model-for-the-circular-economy

https://www.outsideonline.com/2070151/secret-edible-powerhouse-hiding-beer-waste

An Indigo Industrial Ecology Paper – Creating systems solutions for sustainable development through industrial ecology

Agro-eco-industrial parks (AEIP) – From Chapter 6, the Emerging Sustainable Economy, Lowe, Ernest. 2002. Eco-Industrial Park Handbook for Asian Developing Countries, prepared for Asian Development Bank. Click for full Handbook