Regenerative Biorefinery Metrica – Novamont

This case is part of a case series written by Alexander Prinsen. It is the outcome of a research project where dozens of cases where analysed for their potential to merge (eco)Logical Thinking with (eco)Nomic Doing. The cases series are a first summery of main examples which are transformative for their industry. Each of these cases provide breakthrough thinking and scientific evidence how Physics, Biology and Green Chemistry can solve environmental degradation, provide better products, generate profitable business cases and contribute to the whole system we call home, Spaceship Earth.

Author: Alexander Prinsen, Rotterdam, The Netherlands

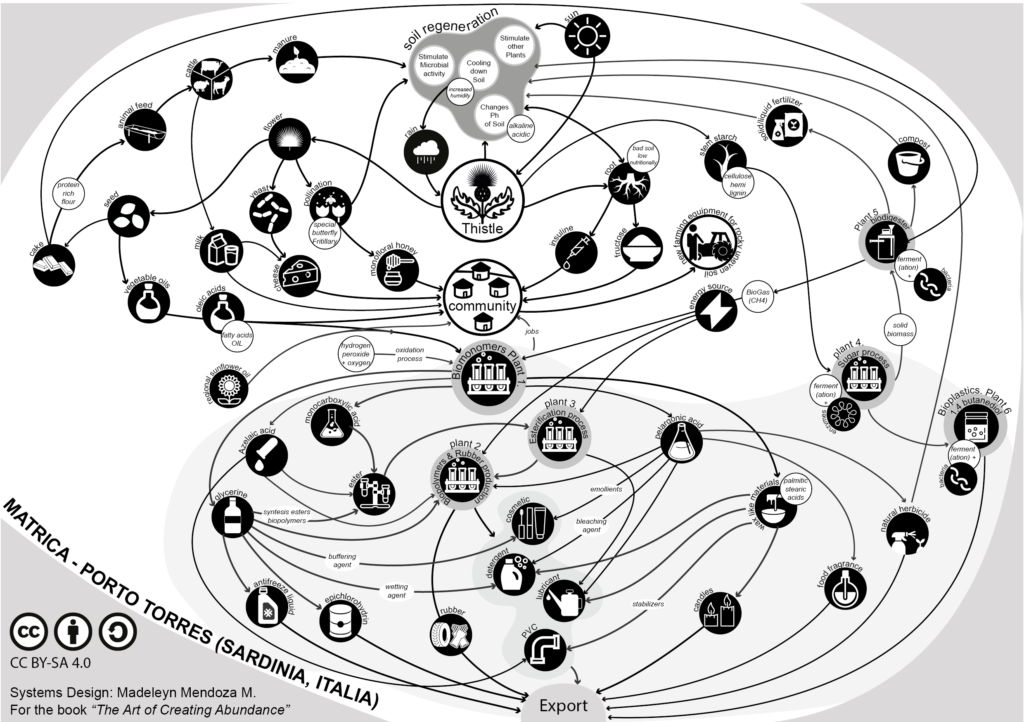

Systemic Design Image: Madeleyn Mendoza M, Turin, Italy

Version: 2 September 2019.

Review status: Permanent Beta version

Tags

Biorefinery; Agroforestry; Integrated farming; Soil restoration; Bio-chemicals; Livestock; 5 kingdoms of Nature; enzymes; Stranded Assets; Thistles, Artichoke; Pesticides; Regional revitalisation.

The relevance of this case

This case explores how a new fossil fuel industrial system is able to produce environmental better forms of plastics and additives using living biomass resources. It offers a transition path for fossil fuel based industry and rise as a new phoenix from its ashes. In this case it shows who the Italian industrial giants are waking up to the new reality and taking action under the visionary leadership of a biochemical scientist. And it shows how this new industrial system can at the same time offer an alternative solution how to solve global soil degradation. It will help understanding how to systematically connect agriculture, refineries and soils in creating profitable business models.

Instead of exploiting finite ancient biomass the fossil fuel industry can transition towards a living feedstock, when maintained restorative, this feedstock can become an endless supply of raw materials at a much lower cost (there is no need to high risk expansive exploration and drilling) in remote high biodiversity regions. The systemic design concentrates itself around the main actor of this success, the original thistle species, Cynara cardunculus, also known as Cardoon. It is the composition of the thistles species which makes its application so interesting. This case helps to explain why and how acids have always been the starting point for plastics and its additives and how a transition towards using living biomass is more than common sense.

It is therefore why this case, Regenerative Biorefinery Metrica, is important. The approach the company Novamont has implemented shows it is actually possible to produce biomass by restoring degraded agricultural land and at the same time not competing with the scarce land for agricultural food production. They have been able to resurrect an agricultural industry through a whole new value chain of stakeholders who have taken responsibility to (re)generate agricultural opportunities, where they are not. And restore the soil and regenerating a whole ecological system at a large scale.

The Matrica biorefinery on Sardinia is the first in its sort where a complete new value chain of bioplastics is being created lead by a Biochemical consortium (Novamont and Versalis-Eni) in close collaboration with the Sardinia farming community. Matrica is the new bio-refinery located on the site of the old oil-refinery of ENI and together the stakeholders have embarked on an exciting journey into a fossil free future. Matrica is a 3rd generation zero waste biorefinery which is setting the industrial standards on how to produce the Bio-chemical of tomorrow being at the centre of an ecological system where nature and industry win.

First we need to understand the current system challenges.

Fossil Fuel industry product impact

The current products derived from fossil fuels (eg. dead biomass) molecules are mostly synthetic (medicines, plastics, additives, pesticides to name a few), meaning they are manmade and did not exist before within our Spaceship Earth. It is because of its very synthetic nature, its end of life transformation is now becoming an existential threat to human species. These molecules are now becoming part of the human species indigestive systems (through indigestion of food, water and inhalation) and also impacting all the other Kingdoms of Nature living systems negatively on a molecular level. To resolve this negative spiral of degradation of living species there is a need of finding alternatives which are do no harm and as such can degrade in the natural world. This transition is also being accelerated knowing fossil fuel, primary the fossil oil component (the gas, LNG, has enough supply for decades to come and is interesting enough very similar to biogas) will eventually run out anyway.

Biobased agricultural Transition challenges

This transition faces a big challenge. This is because the transition needs to balance the available agricultural land for Animal (including humans) species food production and for the production of molecules required for the biobased products. This automatically leads to the most asked wicked question; How will the humans species be able to feed 10 billion humans, feed their livestock and produce sufficient plant species for the production of biobased products in 2050?

The transition becomes more challenging when you add up the fact our spaceship soils have only less than 60 years’ of harvest (from 2015 onward) left. At the moment already one third of total land capacity for agriculture is lost due to degraded soil practise and this will increase rapidly over the coming years. With an aggregation of effects like sea level rise is impacting increased soil salinity and changing weather patterns are drying or wetting the soil impacting yields, the availability of soil will become increasing more important.

Technocrat solution directions

One solution direction put forward by technologists is asking our plant species to increase their yield on less land. This answer has promoted by actively genetically altering the plant DNA to asking it to become a super plant. Although this has proved to success for the green revolution in the 70’ies (reference Wizard and Profit main actors) and was able to feed the growing human population, it does not have a suitable answer how to reverse soil degradation, bring more degraded agricultural land back into production and restore water aquifers. Another technological solution direction is to grow food through industrial greenhouse production systems close to customers to solve the reducing available agricultural land. Both of these solution directions avoid dealing with the main issue, soil degradation and the very dependency of animal species existence.

Agroforestry solution direction

One can also approach this wicked question from a different perspective. What if it would be possible to bring the degraded agricultural land back into production? And request from the restored agricultural soil land to produces more value added products (more multiple cash flows) per hectare for years to come. This solution direction uses the eons of historic resilience and survival tactics the plant species have applied as starting principle. For this to be successful it requires the agricultural system to adapt to regenerative farming techniques on one side. And on the other side it needs to valorise all plant biomass in such a manner it creates a positive cascading system and value added product streams in the whole value chain.

I have to admit to you implementing this last solution direction requires a multidisciplinary approach combining the knowledge from various scientific areas. This case is able to achieve the following goals simultaneously.

1) Integrated crop valorisation approach increases Farmer income

2) Closing nutrient flows to benefit Soil restoration (increasing soil fertility, nutrient cycles and humidity balance)

3) Cascading agricultural products are able to generate high value product streams

4) Symbiotic farmer & bio-refinery collaboration produces high value speciality chemicals and resource effectiveness

Soil regeneration as starting point for good business

One of the main multipliers in this case is soil regeneration. Using the characteristics of the thistle species it is possible to build an integrated agricultural system where the cascading and valorisation of biomass molecules is maximised. The crop produces a large variety of secondary products which are used to optimise the whole value chain and this makes it possible to close the nutrients flows. We will learn how a pioneering plant species, the Thistle, has the capacity restoring unfertile soil and bringing back microbial and plant biodiversity.

Regional Economic growth

Smart cascading of the available resources generates lower costs for farmers (fertilisers are generated by the biorefinery and provided for free to the farmers), agricultural leftover thistle waste is used for additional product transformation (and as such farmers are paid for both the seed and plant production) and natural growing yeasts on the thistle flowers are harvested for dairy fermentation. The outcome is farmers are paid for what they product and as such gain a much higher income). For a long time this intervention was seen too good to be true by business and scientists and as such it was the holy grail of farming. It has been questioned whether earning a better income for farmers and good stewardship over the land would actually be a working business model.

Systems Design

The Novamont approach set out to tackle various issues at the same time. Why their approach is so successful is because their purpose is deeply rooted into their decision-making processes. This case will show how thistles commonly seen as weed species can be put to their full potential. With the knowledge how Los Gaviotas case actually was able to restore their soil on a large scale, and showed how many climate positive related feedback loops and business opportunities were generated.. Let us dive deeper into the systemic design of its value chain.

Introduction to Sardina and Novamont

This case reviews Novamont flagship biorefinery in the city of Porto Torres located on the island of Sardinia (Italy). This flagship biorefinery was able to rise from its ashes through a series of unfortunate events. The first event happened when the low cost oil from Libya dried up supplying the oil refineries from ENI in Italy were faced with closure. The second event was the Porto Torres oil refinery in Sardinia was one of the most polluting refineries in Italy and cleaning the site was going to be an expensive operation. Thirdly the realisation by ENI that its oil refineries in Italy were becoming Stranded Assets and a high need emerged to find solutions for their nine Italian sites. Fourth it was Novamont who was seeking a large scale pilot refinery where they could implement a complete new green economy based on non-food crops sourced from local and regional resources. And so a unique alliance emerged leading the way of a green regenerative economy will look like.

It is the visionary leadership of Catia Bastioli who trained as a (bio)chemist, has been able to unite the Italian chemical and agricultural sectors into a global first biochemistry cluster, leading Italy into the Post Fossil Fuel era. During her career Bastioli worked on solutions how chemistry could reconnect with biology again. In her vision it should be possible to operate a bio-refinery which could combine regional agricultural (re)generation with (Bio)chemistry and have a profitable business model.

How it all come to be, is a story about how the Italian Chemical and Food industry found themselves stuck in ideologies around 1970’ies. The seeds of Novamont originate from the collaboration between Montedison (Italian chemical and energy conglomerate) and Ferruzzi (food company) who set up a joined research collaboration around 1989 to innovate within the field of bioplastics. The joint venture did not succeed and the research team cofounded by Bastioli created Fertec (Ferruzzi Research and Technology). Over the years Fertec started to up build evidence how the Bastioli’s dream would be possible by integrating (Bio)Chemistry, Agriculture and Environment together.

Bastioli and her team realised a gigantic leap was needed to shift from food competing biofuel crops to alternative crops, while at the same time opening up the opportunities to substitute products coming from the existing fossil fuel industry. In addition the team was seeking to replace palm oil ingredients to reduce the environmental impact of palm oil production. It was not shortly after Novamont emerged as the first Phoenix from the ashes. And Bastioli could lead the industry the way towards a new promising future for the Italian (Bio)Chemistry industry.

Since the creation of Novamont Bastioli her team has done what many thought was impossible. Bastioli ensured Novamont works with a defined set of principles and guidelines for the solution direction they want to realise. Their ambition is bold, Novamont wants to become an Innovation leader in biological chemicals. Their first major breakthrough was using corn starch, leftover from maize production, as building block for bio-plastic, MaterBi. The use of thistles was their Novamont next big project and to also replace palm oil with the acids they could extract. So what makes this 3rd generation Zero waste Biorefinery so unique in the wold.

The systemic design of the business model

Within the system design of Novamont approach it becomes clear it is build-upon the integration of their three visions, (eco)technology, Ecology and Social. Firstly their (Eco)technology vision dictates Novamont Industrial process are done without toxins using only Green Chemistry. Novamont prefers to use existing oil-refineries which have become stranded assets for their bio-refineries transformation. Secondly their Ecological Vision revitalizes the connection between biochemical industrial base and (Italian) agricultural regions by reclaiming abandoned agricultural using low impact crop species. Thirdly their Social vision, which is actually their main objective, to generate high value jobs in what are now poor agricultural regions through restoring biodiversity of adapting integrated farming techniques. While at the same time this ensuring the profit margin of farmer’s increases using higher value crop species besides wheat.

So the systemic design of Novamont always integrates and embeds two systems into the local region, the Agriculture and local community cascading system (upstream) and the integrated biorefinery valorisation system (downstream). This approach made it possible to unite whole value chain stakeholders behind the new system. The farmer alliance with Coldiretti (Italys National Farmers Federation) and Consorzi agrari d’Italia (Italian agricultural consortia) committed to start producing from the abandoned farmland again. The close collaboration with the local university (University of Sasarri) and research centres (CNR in Sassari) strengthen the build-up of the region knowledge again.

Upstream System: Agriculture System

The Sardine agricultural system collapsed when the local climate was not able to sustain the wheat species. The European Union decided to implement an agricultural subsidy program to compensate the farmers with for their income loss. This stimulated the farmers to stop working on their low fertile land and leave it to be. And interesting enough this unfortunate event is the beginning of the restoration of their infertile soil. It turned out this type of soil had just all the right conditions, low fertile soil, little water and dry sunny summers, to thrive on the island and as such it did over the decade that passed.

Before we can start explaining the system, first we need to understand the thistle. The original thistle species, Cynara cardunculus, also known as Cardoon, is part of the artichoke family. They differ from the wild species; they can grow over 2 meters tall; have less prickles; have thicker leaf stems (edible leaf stems); and larger flowers. There are over 14 thistle species which are part of the sunflower family. Some thistles are poisonous for animals and humans, while others are a cuisine. The thistle species most of us know is the edible artichoke species (globe artichoke, eg Cynara cardunculus var. Scolymus). It is thought the Arabs and Romans have started cultivated the wild thistle into the more edible artichoke species, having less prickles are more edible yield. Thistles like warm and dry climates and is said they originate from the Mediterranean.

Soil restoration capacity

The thistles are pioneering plant species which grow on land too hard for other species to sustain themselves. The soils generally are nutritionally poor, either too acidic or too alkaline. Thistles have the capacity restoring soil qualities as they have some interesting tricks up their sleeves. It is due to their rigid root system which is bringing all these ecological changes. Their roots loosen up the soil increasing the oxygen concentrations, proving a habitat for microbial life and worms. This increases the water retention capacity of the soil while at the same time the Thistles protect the soil, reducing the soil temperature as result. This changes the soil pH, creating an opportunity for other plant species to populate the area. And until the rain comes back to the area, the Thistle roots have the capacity to find deep in the soil the remaining water in the aquifer, where they have the capacity to also store access water in times needed. Interesting enough the strength of the roots come from their fast metabolise capacity transforming available sugars into fibres. It is therefore not a coincidence their roots are full of insulin and fructose which can be used as feedstock or human consumption as delicately. This effect stimulates the growth of microbial biodiversity in the soil again and contributes restoring the soil hydrogen, nitrogen and carbon cycles.

This positive upward spiral attracts other plant species to shoot their roots and assist in further restoring the soil. Interesting enough thistles tend to move out when the canopy starts to close and more plant species are able to survive in the improving conditions. Suddenly the abandoned agricultural land becomes fertile again thanks to the pioneering work of the thistle as a weed species. (*Beyond the War on Invasive Species: A Permaculture Approach to Ecosystem … By Tao Orion) In the Las Gaviotas case you can read more how pine trees have achieved the same result.

Biological uniqueness

The most remarkable trait of the thistle is its ability to concentrate high levels of biomass and oil in absence of abundant water. It is able to extract the few available minerals and nutrients from the soil using a highly efficient metabolic pathway which allows it to grow into a 2 meter high creature containing a high volume of cellulose, hemicellulose and lignin, and its seeds containing high volume of oil, Oleic Acid (a monounsaturated omega-9 fatty acid). It can be harvested under right conditions twice a year, in autumn and during the winter months. Because of its fight of survival thistles contain naturally high volume of natural pesticides and other highly value chemical components.

The sharp prickles on the leaves and stem of the thistles come therefore not as a surprise as it needs to protect themselves from animals eating them as they prefer to grow on the degraded land, with little other vegetation around them. This is a welcome feedstock source for animals that have little else to choose from in these areas.

Biodiversity accelerator

Thistles have as such an important ecological role to play. The Thistle flower plays an important role for the local beehives communities as food source for their honey (their mono-floral honey is seen as a delicacy product). And as the main pollination hub for butterfly species like the pearl-bordered fritillary, small pearl-bordered fritillary, high brown fritillary and dark green fritillary) pollinating also the surrounding flowing plants. In addition enzymes found on the flower bud are excellent for local cheese production continuing a regional tradition of goat and sheep cheese making practised in the Mediterranean area (famous are Spain and Portugal). The thistle seeds also attract a unique species of goldfinches.

Equipment

In addition the farming equipment sector gets a boost creating a new economy sector of farming equipment suited for uneven and rocky soils.

Thistle processing

When the thistle seeds are harvested the thistle seed oil (the oleic acids) is pressed out of the seeds to be used for the bio-refinery downstream. The seed waste (the cakes) is full of protein which can be converted into flour for animal feed for the local livestock producing the milk, the special cheese using the thistle flower enzymes and meat. The manure from the livestock is used to fertilize the soil to further increase the soil fertility. The Thistle stems are separated and transported to downstream fermentation factory (Plant 5) to be broken down to sugars to be used to produce Bioplastics and Fertiliser. So now the Agricultural circle is closed.

At the moment Metrica uses over 500 HA with over 50 farmers and another 2000 HA is readily available when the biorefinery starts to upscale.

System 2: Downstream the Biorefinery System

After pressing of the thistle seeds the seed oil is mixed with Mediterranean regional sunflower oil (as we have learned both are from the same species and therefore contain oleic acid) before it is ready to be transformed in Bio-Plastic products.

Now the seeds are processed it is time to for the downstream part of the system, the biorefinery of Metrica, to do its work. Why the thistle and sunflower seed oil are so interesting is because these seeds contain high concentration of Oleic Acid [https://en.wikipedia.org/wiki/Oleic_acid] a Monounsaturated omega-9 fatty acid and it is comes with a pallet of other interesting acids. And with the many seeds these plant species produces the oil comes thus in large volumes.

The Matrica refinery system extracts these acids as starting point for further biochemical alterations producing various high value intermediate products.

Factory 1

This is Bio-Monomerss plant (Bio-refinery) vegetable oils into chemical bio-monomers + bio-intermediates (azelaic + pelargonic acids). One of first process innovation Novamont applied was finding a non-toxic oxidation solution to pre-treatment Oleic Acid for further processing. Instead of using Ozone (a toxic gasses) they used non-toxic Hydrogen peroxide and Oxygen [*Liquid Phase Aerobic Oxidation Catalysis: Industrial Applications and …, edited by Shannon S. Stahl, Paul L. Alsters]. This generates the five different acids (Azelaic acid, Pelargonic acid, Glycerol/glycerine, Monocarboxyl acids, Palmitic Stearic Acids) fractions which are further processed on site.

—Box

(A) Azelaic acid (dicarboxylic, difuncitonal acid) which acts as an input for Compostable plastics, Plasticizer for PVC (through the Bio-plastic plant) and as ester synthesis for lubricants (through the lubricants process).

(B) Pelargonic acid or Nonanoic acid are intermediate for Lubricants, Emollients for cosmetics, Bleaching agent, Food Fragrance and Natural Herbicide (which is the reason why the thistle is able to outcompete other plants).

(C) Glycerine / Glycerol is a polyol (and a sugars type) which is used for Emollient, Wetting agent, Buffering Agent for cosmetic products, Anti-freeze liquid, as synthesis of esters for bio-polymers and an intermediate Epichlorohydrin used for epoxy glues and resins, and elastomers. It can also be used as cosmetics replacing Palm Oil using the Azelaic & Pelargonic acid and Glycerine.

(D) Monocarboxyl acids blend (5 to 9-carbon stings). These acids can be converted into Esters bases to be used in high performance lubricants, like aeronautics.

(E) Palmitic Stearic Acids (Saturated Fatty Acids) blend. These are wax-like materials used in Detergents, Candles, Lubricants, Cosmetics and for PVC stabilizers.

Box —-

Factory 2 Bio-lubricant plant

The 2nd factory (Plant 2) combines the Azelaic acid, Glycyerol and Pelargonic Acid to produce various Bio-Polymers and Rubber products.

Plant 3: Bio-additives for rubber and Bio-Fillers

The 3rd factory (Plant 3) is an esterification process to refine acids as input for the Bio-polymer plant.

Plant 4 + 6 Processing and fermenting thistle stems

Also the Thistle stems get used. They contain high valuable Lignin and (Hemi)Cellulose which are converted into simple sugars (Plant 4) which than can be fermented by bacteria into 1,4 Butanediol (Plant 6) to be used as solvent to make Plastics like Elastic Fibres and Polyurethanes (PE).

Plant 5: Waste 2 Energy plant

The remaining biomass left [approximate 20% of the volume] (leaves, stem and other parts) consisting of cellulose, hemicellulose and lignin is used to produce energy. It is directly burned for energy or put to use a biodigester (Plant 5) for methane production. The digester provided liquid and compost fertilizer for the local farms, which is free of charge.

Product Stream Summery

In total the biorefinery makes the follow products:

(I) Bio-polymers; (II) Tire industry Bio-additives which improve rolling resistance, reduce fuel consumption and improve tyre grip in wet conditions; (III) nontoxic Polymer Plasticizers; (IV) (Bio)Lubricants based on the Azelaic & Pelargonic acids which interesting enough naturally decompose minimizing aquatic ecosystems); (V) wetting agents for Detergents; (VI) non-toxix Bio-herbicides; and (VII) Cosmetics ingredients which can replace Palm Oil.

Realism

Novamont has been moving into the Green chemistry path for more than two decades defining the existing business logic.

From the start the Novamont team had to convince academics, business and government that the bio-refinery concept is the way forward. Through their perseverance and their capacity to unite the Italian Chemical Industry and Farming networks, they put Italy at the forefront of the biobased economy. Their innovative thinking has led to a large number of ground breaking new biotechnology and process technology as industrial standard. And Metrica is setting the global standard how the bio-refinery concept can be setup.

Ironically or just being at the right time at the right moment, their success is directly linked to the demise of the Italian fossil oil industry due to the disappearing of cheap fossil fuels from Libya. Novamont had the opportunity to transform a stranded polluting refinery to their specification, without large upfront investment. With the help of European Union Funds and a smart financial strategy the team was able to put a 500 million euros investment to action. Today all nine Italian oil refineries have been refitted and converted into working bio-refineries by Novamont using degraded agricultural land output as their feedstock. Italy has become a roundabout of a revitalised agricultural system where the degraded soil is producing products for these nine bio-refineries. This new regenerative biobased industrial cluster is restoring the farmland, improving the lives of farmers and importantly is showing to be competitive on the international market.

The uniqueness of thistles is it is the cheapest crops for raw materials in the world, they require no water and no pesticides, they grow on non-fertile soil and one only needs to harvest them for input in industrial systems. A win win for all stakeholders. The farmers sudden have access to cheap food for their animals; they can fertilize their farmland and can sustain their local food production tradition. Slowly the thistle is turning into an ally in the human pursue for sustainable substitutes.

As one of the very few manufacturers Novamont is setting standard how an integrated Social, Ecology, (Eco)Technology and Economic vision can create innovative and profitable business models and doing good at the same time. Their design criteria using input feedstock’s which is not competing with food crops ensuring more land can used to produce food is key to their success. It pushed the scientists to consider other alternatives beyond the obvious and defined where to look for the solutions. As such they are leading the way on how to use neglected crops in a regenerative manner to keep up the demand for biochemical and accelerate the transition towards renewable biochemical. Novamont is continuing their search for other crops that fit their criteria to generate a value added chemical spectrum of opportunities and have a positive global climate impact. The list of innovation is constantly growing, their newest fermentation refinery converting crop sugars into butadiene adding another chemical intermediate to their growing list. In the coming years more projects will get on-stream using unexpected crops and interesting cascading solutions.

It is therefore not so strange Novamont is also founding member of a complete new Green Chemistry post master program to share their insights with the global chemistry community.

This case shows humans need to redefine how they look at weed species. As it turns out with the thistle species they are actually very beneficial once it is understood why they are as they are. This implies there is much more to learn from other weed species, which could hold many more keys in solving many of the challenges humans face. It also shows a solution direction on how farmers can actually collaborate with weeds for their beneficial traits. This will flip agricultural practise upside down for years to come.

The options how to put the emissions (CO2, NOx, SOx etc) created by combustion (or fermentation) of dead biomass to use is explained in another cases (Lanzatech and Brewery). These cases will explain in more detail how combustion can actually be a good thing when the loops (recycling. Reuse, Repurpose) of these emissions are closed.

Sources

Matrica

http://www.euronews.com/2015/07/14/sardinian-plant-gets-second-life-in-biodegradable-plastics/

http://www.matrica.it/article.asp?id=26&ver=en#.Vq9MZlIl-DM

http://www.novamont.com/eng/novamont-in-italy

http://www.chemicals-technology.com/projects/the-matrca-project-porto-torres-sardinia/

http://www.novamont.com/eng/leggi_press.php?id_press=6

Video about the farming community

http://www.acme-hardesty.com/sustainability/bio-based-chemical-industry/

http://www.acme-hardesty.com/sustainability/bio-based-chemical-industry/

http://bioeconomy.miur.it/wp-content/uploads/2014/11/Bastioli-Bioeconomy-Conference-CB2-vf.pdf

Novamont

A CIRCULAR APPROACH TO BIOECONOMY – an opportunity to decarbonise the economy and reconnect it with society- 2017 by Bastioli [https://www.novamont.com/public/Pubblicazioni/Lectio%20Magistralis%20Bastioli_2008_eng.pdf]

https://www.bio.org/sites/default/files/1030AM-%20Stefano%20Facco.pdf

Biorefinery

http://www.gunterpauli.com/blog/reindustrialization-beyond-globalization

Chemicals and Fuels from Bio-Based Building Blocks, By Fabrizio Cavani, Stefania Albonetti, Francesco Basile, Alessandro Gandini